The CNC Aluminum Extrusion Milling Drilling Machine is a highly advanced and specialized piece of equipment designed for precision machining in the window and door manufacturing industry. This machine is particularly essential for creating lock holes, hinge bores, and other critical features in aluminum profiles used for doors and windows. Below is a detailed overview of its features, applications, and advantages.

1. Key Features and Capabilities

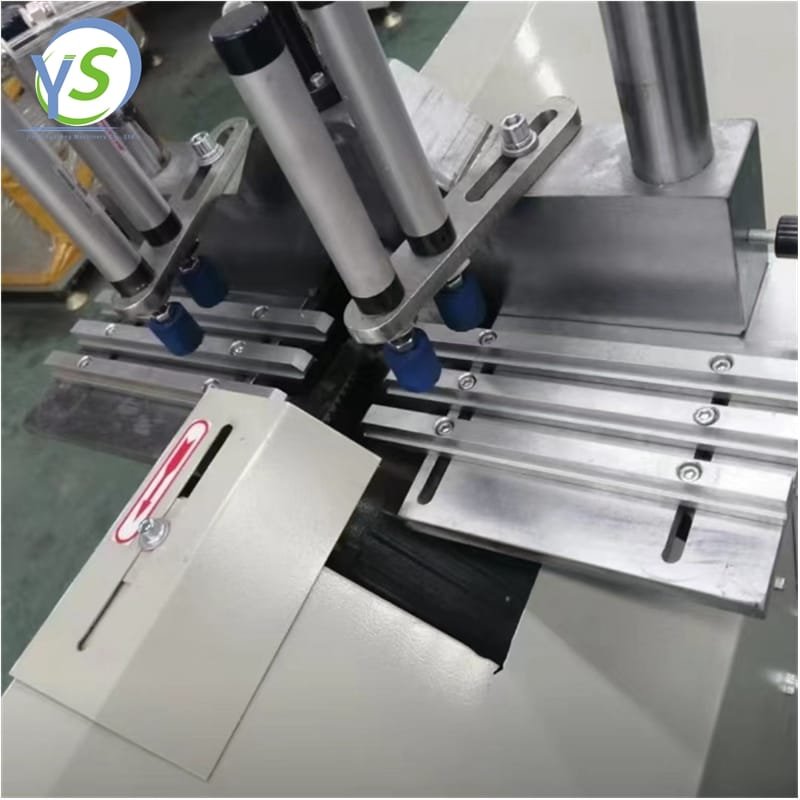

- Multi-Axis Machining: Typically equipped with 3-axis or more, allowing for complex milling, drilling, and engraving operations in a single setup.

- High Precision: CNC-controlled movements ensure accurate hole positioning, essential for proper lock and hinge alignment.

- Automated Operation: Reduces manual labor and minimizes errors, improving production efficiency.

- Versatility: Capable of handling various aluminum profiles, making it suitable for different window and door designs.

- Tool Compensation: Automatic tool length and diameter compensation ensure consistent machining quality.

2. Applications in Window and Door Manufacturing

This machine is widely used for:

- Lock Hole Drilling: Precisely drills holes for mortise locks, deadbolts, and other locking mechanisms.

- Hinge Machining: Creates accurate hinge recesses for smooth door operation.

- Milling Grooves & Slots: Essential for sliding window tracks and other structural features.

- Engraving & Marking: Adds serial numbers or branding to aluminum profiles.

3. Advantages Over Traditional Methods

- Faster Production: CNC automation significantly reduces cycle times compared to manual drilling.

- Higher Consistency: Eliminates human error, ensuring uniform quality across all workpieces.

- Flexibility: Easily programmable for different window and door designs without mechanical adjustments.

- Cost-Effective: Reduces material waste and labor costs in the long run.

4. Industry Adoption

Leading manufacturers, such as Parker Machinery Co., Ltd, have developed specialized CNC machines for door and window production, including the DMCC82 CNC Door Lock & Hinge Drilling Machine, which is optimized for high-speed, high-precision hole-making in aluminum extrusions.

Conclusion

The CNC Aluminum Extrusion Milling Drilling Machine is a cornerstone of modern window and door fabrication, offering unmatched precision, efficiency, and adaptability. Its ability to automate complex machining tasks makes it indispensable for manufacturers aiming to enhance productivity while maintaining superior quality standards.

(Note: This article is based on industry-standard CNC machining practices and manufacturer specifications for window and door production equipment.)