Introduction

In the manufacturing field of plastic-steel doors and windows, the CNC corner cleaning machine plays a vital role. It is a specialized piece of equipment designed to precisely process the corners of plastic-steel door and window frames, ensuring high-quality finishes and excellent performance.

Working Principle

The CNC corner cleaning machine operates based on advanced numerical control technology. It is equipped with precise cutting tools and a well-programmed control system. First, the operator inputs the specific parameters of the door and window frame’s corner shape, size, and the required processing precision into the machine’s control panel. Then, the machine’s mechanical components, driven by servo motors under the guidance of the programmed instructions, accurately position the workpiece. The cutting tools start to work, removing the excess materials at the corners with high speed and accuracy, making the corners smooth and meeting the preset standards. For example, it can precisely control the cutting depth and angle to create a perfect right angle or other specific angled corners according to different design requirements.

Advantages

- High Precision: Thanks to the numerical control system, it can achieve extremely accurate processing results. The tolerance of the corner dimensions can be controlled within a very narrow range, which is crucial for ensuring that the assembled plastic-steel doors and windows have a tight fit and good sealing performance.

- Improved Efficiency: Compared with traditional manual or semi-automatic corner processing methods, the CNC corner cleaning machine can complete the processing of multiple corners in a short time. It can continuously handle a large number of workpieces without significant manual intervention during the operation process, greatly improving the overall production efficiency of plastic-steel doors and windows.

- Consistent Quality: The machine guarantees that each corner processed has the same high quality. There is no significant variation in the appearance and dimensions of the corners from one workpiece to another, which helps to enhance the brand image of the plastic-steel doors and windows products and win the trust of customers.

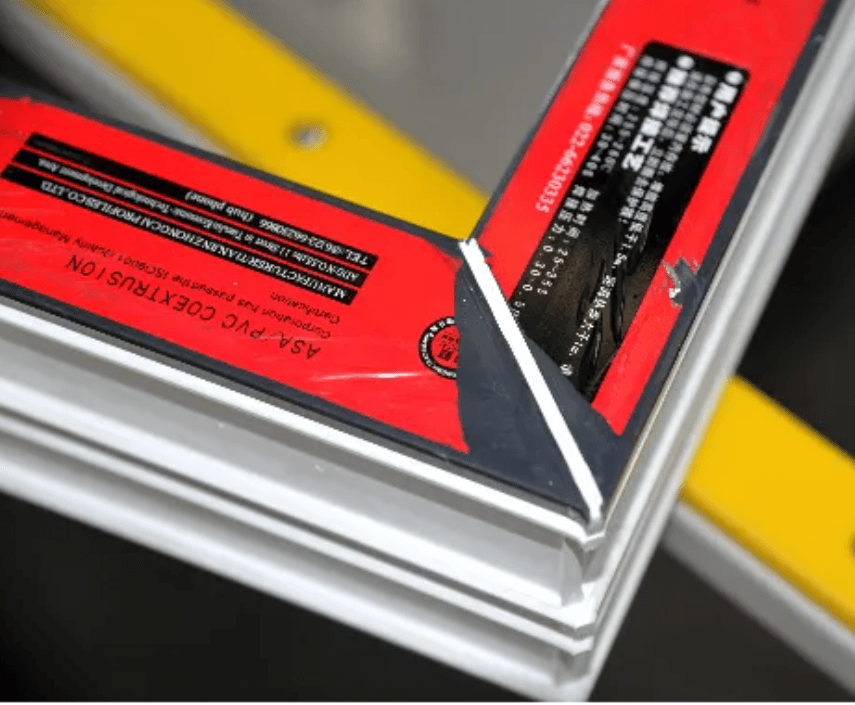

Structure and Components

It mainly consists of a machine body, a worktable for placing the plastic-steel door and window frames, a cutting tool system, a numerical control system console, and a transmission mechanism. The machine body provides a stable support structure. The worktable is designed to firmly hold the workpiece in place during processing. The cutting tool system includes various types of cutting blades or grinding wheels that are replaceable according to different processing needs. The numerical control system console is the “brain” of the whole machine, where operators can set parameters and monitor the running status. The transmission mechanism ensures the smooth movement of the worktable and the cutting tools to achieve accurate positioning and processing.

Application and Significance

In the production process of plastic-steel doors and windows factories, the CNC corner cleaning machine is widely used. It not only helps to improve the quality of the final products but also enables manufacturers to meet the increasing market demands for better-looking and more durable doors and windows. Moreover, it promotes the standardization and modernization of the production process, making the production line more efficient and competitive in the industry.

In conclusion, the CNC corner cleaning machine for plastic-steel doors and windows equipment is an indispensable and important part of the modern manufacturing process of plastic-steel doors and windows, bringing numerous benefits to both manufacturers and end-users.