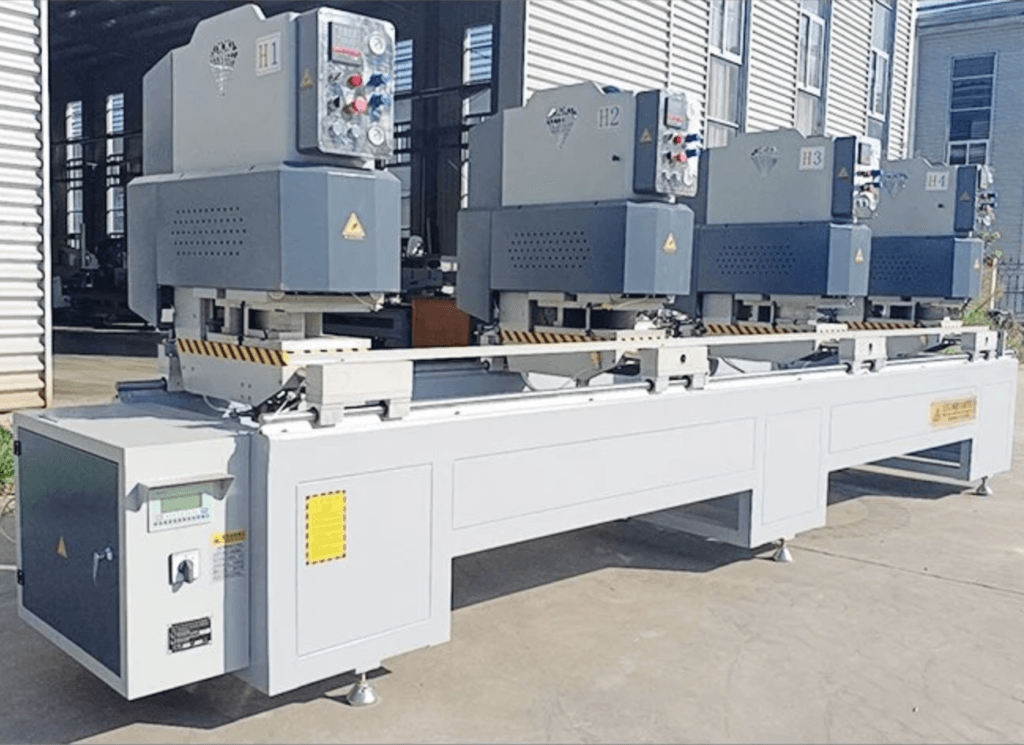

In the world of woodworking and manufacturing, precision and efficiency are paramount. The double-head cutting saw is a revolutionary machine designed to meet these demands, offering unparalleled accuracy and productivity for cutting various materials, including wood, aluminum, and PVC.

What is a Double-Head Cutting Saw?

A double-head cutting saw is an advanced cutting machine equipped with two parallel saw blades that operate simultaneously. This design allows for high-speed, symmetrical cuts in a single pass, significantly reducing production time while maintaining consistent quality.

Key Features and Advantages

- Dual-Blade System – The two synchronized blades enable simultaneous cutting on both ends of a workpiece, ensuring perfect symmetry and eliminating the need for repositioning.

- High Precision – Equipped with advanced laser guides and digital controls, these saws deliver exact measurements with minimal deviation, crucial for fine woodworking and cabinetry.

- Versatility – Capable of cutting various materials (wood, composites, plastics, and metals), making it ideal for furniture making, flooring, and window frame production.

- Increased Productivity – By performing two cuts in one operation, it reduces processing time and labor costs, enhancing workflow efficiency.

- Adjustable Angles – Many models feature angle-adjustable blades (0° to 45°), allowing for beveled and mitered cuts without additional setups.

Applications

- Furniture Manufacturing – Cutting table legs, frames, and panels with perfect uniformity.

- Door and Window Production – Precise trimming of aluminum or wooden profiles.

- Flooring and Decking – Efficiently processing hardwood or laminate planks.

Conclusion

The double-head cutting saw is a game-changer for industries requiring speed, accuracy, and repeatability. By integrating this machine into production lines, businesses can achieve higher output, reduced waste, and superior craftsmanship, making it a worthy investment for modern workshops.

Would you like recommendations on specific models or brands?