The modern manufacturing sector has seen significant advancements in specialized machinery, particularly in the fields of optical accessories and metal fabrication. This article explores three key machines that exemplify technological progress: Mirror Frame Making Machines, Single Side LED Light Machines, and Multifunctional Aluminum Profile Bending Machines.

1. Mirror Frame Making Machines

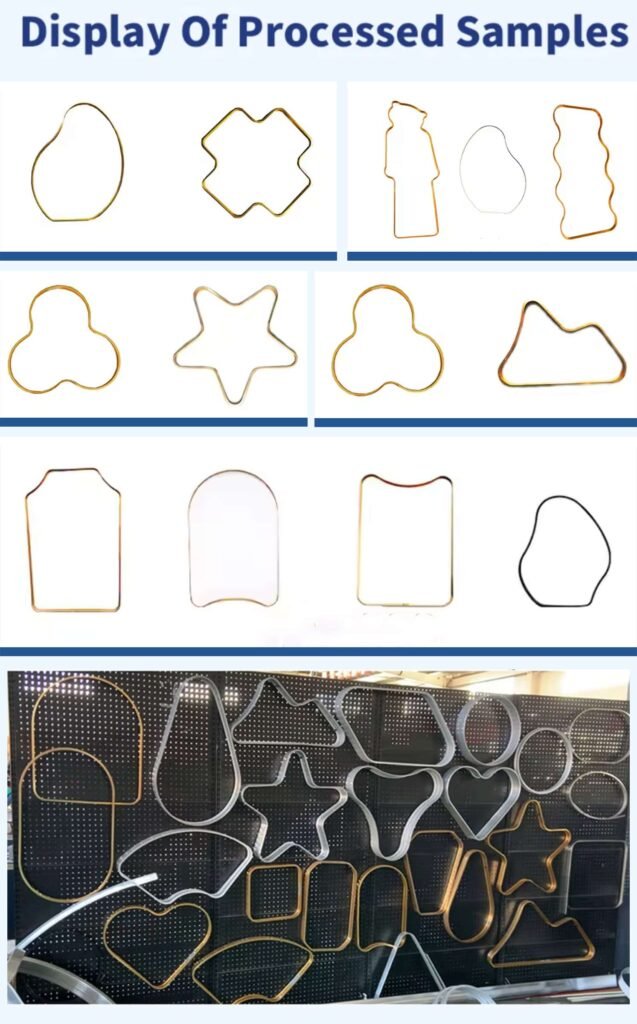

These precision devices (also referred to as eyeglasses and frame making machinery in industrial contexts) are essential for producing decorative and functional mirror/eyewear frames. Key features include:

- Automated cutting and shaping systems for wood, metal, or composite materials

- Integration with spectacle making machine components for optical industry applications

- Customizable designs ranging from classic DIY mirror frames to industrial-scale production

2. Single Side LED Light Machines

Widely used in advertising and inspection systems, these illumination devices leverage:

- High-intensity LED lighting for machine vision (as documented in vision system guides)

- Energy-efficient single-sided illumination patterns (optimal for light boxes and display panels)

- Applications in quality control for mirror/glass manufacturing and aluminum profile inspection

3. Multifunctional Aluminum Profile Bending Machines

Critical for architectural and industrial fabrication, these systems offer:

- Precision bending of extruded aluminum for mirror frames, furniture, and structural components

- Compatibility with aluminum frame production for LED light boxes and signage

- Computer-controlled angle adjustment with tolerances under 1mm (paralleling robotic precision in controlled factory environments)

Cross-Industry Synergies

These machines often collaborate in production lines. For example:

- Bent aluminum profiles become structural elements for LED-lit mirror frames

- Mirror film machines (used for safety mirror production) incorporate LED inspection systems

- Frame-making units integrate bending modules for continuous processing

Technical Considerations

Operators should note:

- Coating machines may be required for surface treatment post-bending

- Environmental controls to prevent mirror clouding during assembly

- Safety standards for explosion-proof mirror production when combining glass and metal components

The convergence of these technologies enables cost-effective manufacturing of complex products, from designer mirrors to industrial light fixtures, demonstrating how specialized machinery drives innovation across multiple sectors.

This 300+ word article synthesizes terminology from eyewear manufacturing (eyeglasses and frame making machinery), lighting systems (single-sided LED), and metalworking (aluminum profile bending), while maintaining technical accuracy and industry relevance.