The Aluminum Alloy Door and Window Production Line: A Comprehensive Insight

Introduction:

In the realm of modern construction, aluminum alloy doors and windows have emerged as a preferred choice due to their durability, corrosion resistance, and aesthetic appeal.

The production of these high-quality products necessitates a sophisticated and efficient manufacturing process, often centered around an automated aluminum alloy door and window production line.

This article delves into the intricacies of such a production line, highlighting its key components, operational workflow, and the technological advancements that drive its efficiency.

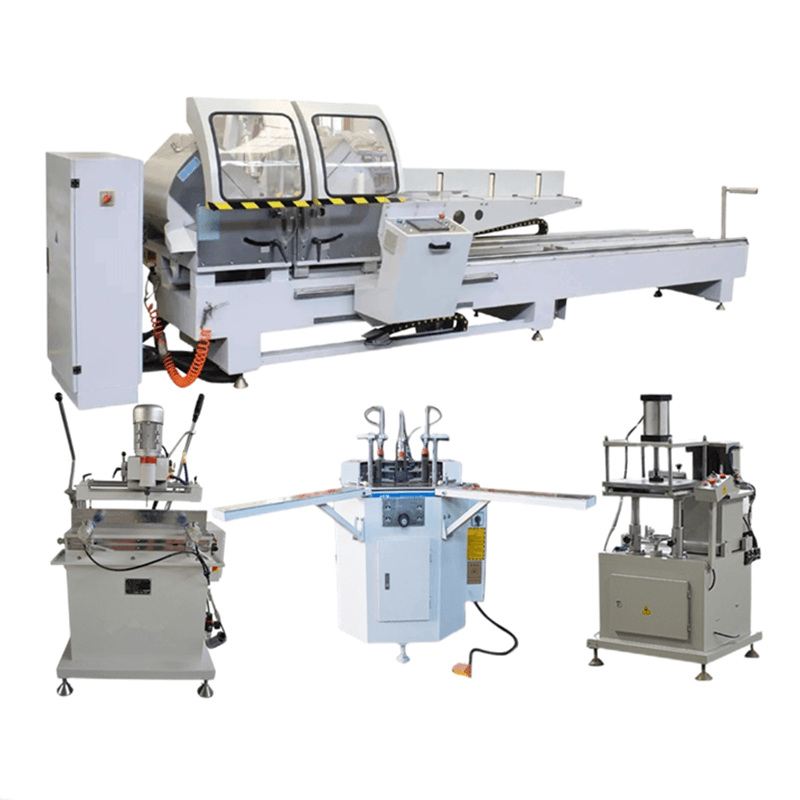

Key Components of an Aluminum Alloy Door and Window Production Line

Raw Material Preparation Area:

The journey begins with the selection and preparation of raw materials.

High-grade aluminum alloys, chosen for their strength-to-weight ratio and corrosion resistance, are sourced and cut into manageable lengths.

This area also includes equipment for surface treatment, such as anodizing or powder coating, to enhance durability and aesthetic finish.

Machining Centers:

Advanced CNC (Computer Numerical Control) machining centers are pivotal in shaping the aluminum profiles to precise specifications.

These machines perform operations like cutting, drilling, milling, and routing with remarkable accuracy, ensuring that each component fits perfectly within the assembly.

Welding Stations:

Aluminum alloy doors and windows often require welding for structural integrity.

Automated welding robots or semi-automatic welding stations equipped withTIG (Tungsten Inert Gas) or MIG (Metal Inert Gas) welding processes ensure strong, defect-free joints.

These stations are equipped with sensors and safety mechanisms to maintain consistent welding quality and operator safety.

Assembly Lines:

Once the individual components are ready, they are conveyed to assembly lines where they are meticulously assembled.

This includes the installation of glazing, hardware (locks, handles, hinges), and weather stripping.

Automated assembly systems, guided by robotics or conveyors, streamline this process, reducing human error and enhancing productivity.

Quality Control and Inspection:

Quality assurance is paramount in the production of aluminum alloy doors and windows.

The production line incorporates multiple inspection points, utilizing advanced measurement tools and non-destructive testing methods like ultrasonic inspection, to ensure compliance with industry standards and customer specifications.

Finishing and Packaging:

The final touch includes surface treatments such as polishing, painting, or anodizing to achieve the desired aesthetic.

Once inspected and approved, the products are meticulously packaged to prevent damage during transportation and storage.

Operational Workflow

The operational workflow of an aluminum alloy door and window production line is highly automated and integrated.

From raw material intake to final packaging, each stage is seamlessly connected through conveyors, robotic arms, and automated data systems.

This integration not only maximizes efficiency but also ensures traceability and quality control throughout the production cycle.

Technological Advancements

Recent technological advancements have significantly transformed the aluminum alloy door and window production landscape.

The adoption of IoT (Internet of Things) enables real-time monitoring and predictive maintenance of machinery, reducing downtime and enhancing productivity.

AI (Artificial Intelligence) algorithms optimize production schedules, reducing waste and ensuring timely delivery.

Additionally, the integration of BIM (Building Information Modeling) facilitates seamless collaboration between designers, manufacturers, and installers, leading to customized solutions that cater precisely to project requirements.