Aluminum Thermal Break Windows Profile Making Line Rolling Compounding Machine

- This aluminum profile rolling machine is to combine thermal barrier strip or plastic profile with aluminum profiles to make the end product, which is called bridge-cut-off aluminum alloy profile or thermal break aluminum profile. Hardened rollers are used to press the knurled profile and thermal barrier strip or plastic profile together, to make a composite profile that has great insulation effect.

- Equipped with three groups of hardened rollers electrically controlled, available in changing profiles quickly with the Nylon rollers. Two-axis direction adjustments.

- Six rollers controlled by separate driving force guarantee stable rolling, higher speed, and higher efficiency.

- Space between roller wheelings adjustable. Suitable for various sizes of thermal barrier strips.

- Frequency converter with stepless speed regulation.

- The transmission mode of the lower profile machine pressure plate is through a transmission shaft, and the digital display adjustment range can reach 0-100mm. The whole machine is lifted and lowered by 0-110mm, driven by a motor and freely adjustable.

- The rack is made of steel plates welded firmly and securely, and the external powder spray cover is beautiful and generous.

- High-precision screw are used for driving.

- By using two hard knurled wheels to thread and hobbe the groove of the aluminum profile. By using a pair of hard material knurling wheels, the groove of the aluminum alloy profile passing through the insulation strip is hobbed to increase the shear force of the insulation profile, achieving simultaneous cutting and threading of the strip.

- Adopting AC variable frequency speed regulation for stepless speed control of gear rolling speed.

- Gear hobbing transmission: The drive motor+aluminum alloy casing worm gear reducer+spindle box achieve precise gear hobbing.

- Adopting imported linear ball guide rails, frequency converters, reducers, and high-precision digital displays.

- Can achieve automated tooth opening and threading function.

Technical Parameter

| Model | FH-02 |

| Voltage | 380V 50HZ ( can be customized ) |

| Power | 4KW |

| Maximum rolling wheel diameter | 230mm |

| Adjustment range of lower roller height | 0-80mm |

| Height adjustment range of upper rolling wheel | 0-60mm |

| Profile feed rate | 0-70m/min |

| The maximum passing size of the profile | 280mm(w)*280mm(h) |

| Dimensions | 950*1650*1750mm |

| Weight | 1000 kg |

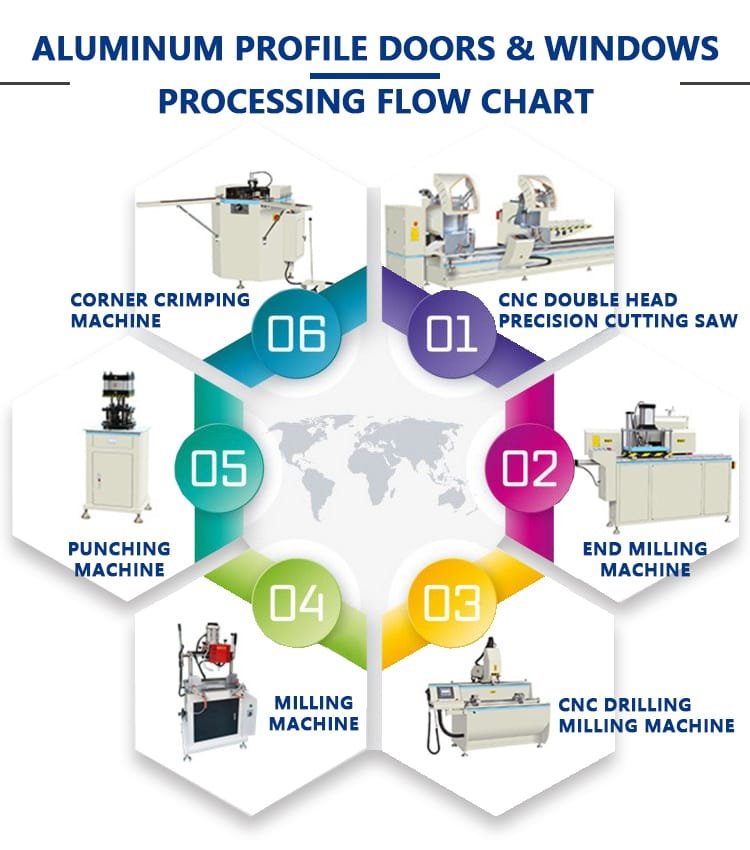

Aluminum Window Door Production Process

About Jinan Yusheng Machinery

Jinan Yusheng Machinery Co., Ltd. is dedicated to the cutting-edge technology of aluminum profiles, doors, windows, and curtain wall processing equipment, as well as the practical application of processing sites. It has a team of experienced and expert employees in the industry, equipped with a large mechanical processing workshop with complete functions. It is a high-tech enterprise that integrates research and development, production, sales, and service. Since its establishment, the company has been committed to the research and development of energy-saving door and window technology, providing complete assembly equipment for aluminum profiles, ordinary plastic steel profiles, and high-end aluminum insulated glass production lines to the industry. The products cover industries such as industrial aluminum profiles, door and window curtain walls, rail transit, aerospace, industrial manufacturing, and household appliances. The company relies on strong technical expertise, rigorous production and processing, and a complete range of equipment to meet the needs of different investment scales. It can also customize personalized products of different grades according to customer requirements.

Creating value for users is our commitment, taking responsibility for each product is our responsibility, and customer satisfaction is the ultimate goal of our services; Winning customer, employee, and social satisfaction is the driving force behind our progress.

With high-quality products and an efficient service team, Yusheng Machinery looks forward to providing you with high-quality products and services!

Certifications

Our Clients

Packing&Delivery

Service

1). At least 1 year from the date of completion of the commissioning.

2). Free consultation service before, during, and after sales;

3). Free project planning and design services;

4). Free debugging of equipment until everything is functional;

5). Free management of equipments long distance shipping;

6). Free training of equipment maintenance and operating personally;

7). Provide 1 year complete warranty and life-time maintenance service;

Reviews

There are no reviews yet.