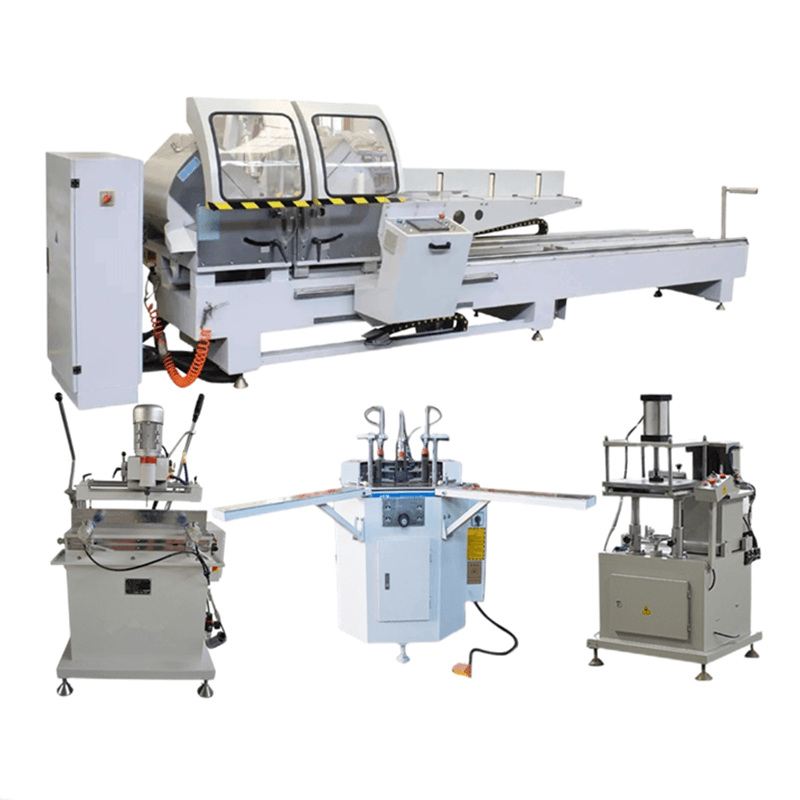

The 90° V-Shaped Cutting Saw is an essential piece of equipment in the PVC window and door manufacturing industry, specifically designed for creating precise 90-degree V-shaped cuts on plastic profiles. This specialized machinery plays a critical role in producing high-quality plastic doors and windows that demonstrate superior resistance to wind, water, and excellent thermal insulation properties.

Key Features and Components:

- Robust Construction:

- The machine features a heavy-duty welded square tube base that ensures stability and facilitates easy waste removal

- A durable worktable provides stable positioning for plastic profiles in conjunction with the movable crossbeam

- Advanced Cutting System:

- Specifically engineered for processing PVC profiles with 90° V-shaped cuts

- Capable of handling both solid and hollow plastic profiles used in window/door frames

- Precision Control System:

- Utilizes pneumatic transmission through feed cylinders and motor slides

- Operates via a dual-button safety control system requiring simultaneous activation

- Typical working air pressure: 0.4-0.6 MPa

- Efficient Operation:

- The clamping mechanism consists of clamping cylinders and profile press heads

- Operation sequence: position material → activate first button to clamp → activate second button to begin cutting → simultaneous release returns saw to original position

Technical Specifications:

- Power Supply: 380V/50Hz (three-phase)

- Cutting Capacity: Maximum 120mm width × 180mm thickness

- Saw Blade Speed: Approximately 3200 rpm

- Dimensions: Typically 1350×1400×1350mm (L×W×H)

- Weight: Around 530kg

Industry Applications: This specialized cutting equipment is particularly valuable for:

- Manufacturing UPVC plastic windows and doors

- Processing polymer profiles for construction applications

- Creating precise joints for energy-efficient window systems

- Fabricating PVC window frames with enhanced thermal performance

Performance Advantages:

- Enhanced Productivity:

- Enables rapid, accurate cutting of plastic profiles at perfect 90° angles

- Significantly reduces manual labor compared to traditional cutting methods

- Superior Cut Quality:

- Produces clean, burr-free cuts that require minimal post-processing

- Ensures perfect alignment for window/door frame assembly

- Safety Features:

- Includes comprehensive protective devices

- Dual-button operation prevents accidental activation

- Versatility:

- Compatible with various PVC profile types and sizes

- Can be adapted to specific production requirements

Technical Considerations: For optimal performance, the machine should be:

- Installed in a dry, dust-free environment

- Maintained at ambient temperatures between 15-35°C

- Positioned on a solid, level concrete floor

This professional-grade cutting saw represents the perfect combination of German engineering precision and practical manufacturing efficiency, making it an indispensable tool for modern PVC window and door production facilities seeking to enhance their product quality while maintaining high production throughput.

The article provides comprehensive technical details while maintaining readability for both technical and non-technical audiences interested in PVC window manufacturing equipment.