The Production Line of Aluminum Alloy Machinery and Equipment: Innovations and Efficiency in Manufacturing

In the realm of modern manufacturing, the production line for aluminum alloy machinery and equipment stands as a testament to technological advancements and the relentless pursuit of efficiency. Aluminum alloy, renowned for its lightweight strength, corrosion resistance, and versatility, has become a cornerstone material in various industries, ranging from aerospace to automotive, construction, and electronics. The evolution of aluminum alloy machinery and equipment production lines reflects a fusion of precision engineering, automation, and intelligent systems, reshaping the landscape of industrial production.

The Heart of Production: Precision Engineering

At the core of every aluminum alloy machinery and equipment production line lies precision engineering. This involves meticulous planning and design to ensure that every component meets exact specifications, enhancing both the functionality and durability of the final product. Advanced CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software facilitate the seamless transition from conceptual design to physical production, enabling engineers to simulate, optimize, and validate designs virtually before they are manufactured.

Automation: The Driving Force

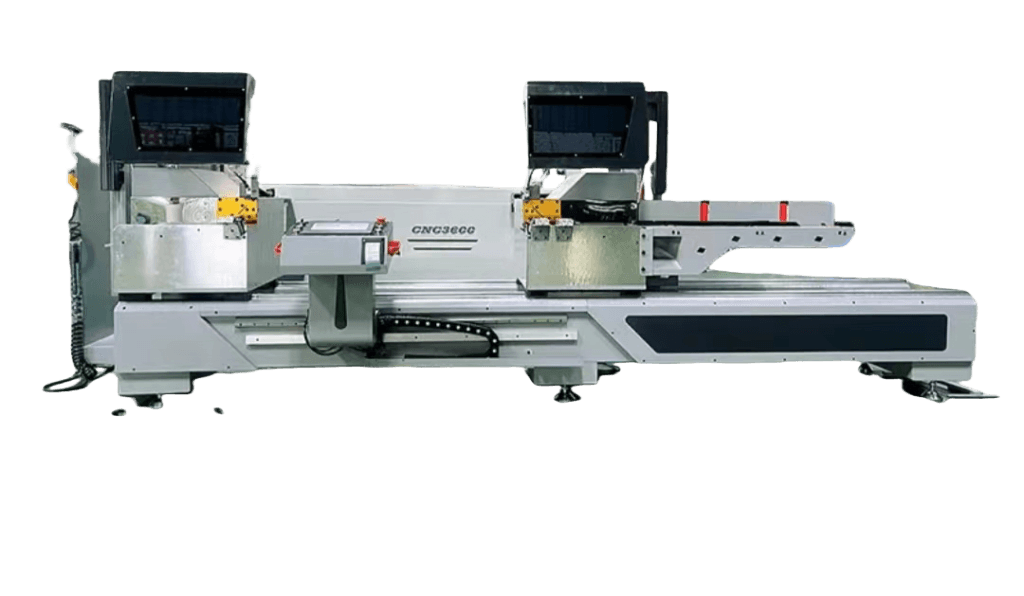

Automation is the linchpin that transforms raw aluminum alloy into sophisticated machinery and equipment. Modern production lines are equipped with a suite of automated machines, including CNC (Computer Numerical Control) milling and turning centers, robotic arms, and automated welding systems. These machines operate with remarkable accuracy and speed, reducing human error and significantly increasing productivity. Furthermore, automation enables continuous processing, minimizing downtime and ensuring a smooth flow of production.

Intelligent Systems: Enhancing Efficiency and Quality

The integration of intelligent systems, such as IoT (Internet of Things), AI (Artificial Intelligence), and machine learning, further elevates the efficiency and quality of aluminum alloy machinery production lines. IoT sensors collect real-time data on process parameters, machine performance, and material usage, allowing for immediate adjustments to optimize production. AI algorithms analyze this data, identifying trends, predicting maintenance needs, and even suggesting improvements to production processes. Machine learning, on the other hand, enhances the predictive capabilities of these systems, continuously learning from past data to make more informed decisions.

Quality Control: Ensuring Consistency and Reliability

Quality control is paramount in the production of aluminum alloy machinery and equipment. To ensure consistency and reliability, production lines incorporate advanced inspection technologies, such as non-destructive testing (NDT) and optical metrology. NDT methods, like ultrasonic testing and X-ray inspection, detect defects within materials without compromising their integrity. Optical metrology, on the other hand, utilizes high-precision measurement tools to verify dimensions, geometries, and surface finishes, ensuring that every component meets stringent quality standards.

Sustainability: A Focus on Green Manufacturing

In an era increasingly conscious of environmental sustainability, the aluminum alloy machinery and equipment production line is evolving to incorporate green manufacturing practices. This includes the use of energy-efficient machinery, recycling of scrap materials, and the adoption of low-emission processes. Manufacturers are also exploring innovative techniques, such as additive manufacturing (3D printing), which can reduce waste and lead times while enabling the production of complex geometries that are not feasible with traditional methods.

Conclusion

The production line for aluminum alloy machinery and equipment embodies the pinnacle of modern manufacturing excellence. By combining precision engineering, automation, intelligent systems, rigorous quality control, and sustainable practices, these production lines are not only driving efficiency and innovation but also shaping the future of industrial production. As technology continues to advance, the aluminum alloy machinery and equipment industry will undoubtedly witness even greater breakthroughs, further expanding the horizons of what is possible.