CNC Automatic 3D Aluminum Stainless Steel Metal Channel Letter Bending Machine

- CNC Channel Letter Bending Machine Aluminum Edge Letters, Resin Luminous Letters, Super Letters (Liquid Acrylic Letters), Aluminum Profile Letters, Aluminum Letters with Sponge, Side Luminous Letters, LED Words and Various Aluminum Luminous Letters, Stainless Steel Letters and words, Tin word and High Polymer Luminous Letters, etc.

- The double manipulator alternating feeding structure is adopted to effectively ensure the stability of the feeding process. The material clamp adopts structural casting, which can improve the feeding grip and avoid scratching the material at the same time.

- Double-knife alternating bending structure, high forming degree and strong stability.

- Automatic adjustment of cutting depth for planer system, easy to operate.

- Maintenance without grinding basically realizes zero-cost operation of equipment. The planer system automatically adjusts the cutter without debugging the cutting depth.

- Software automatically recognizes and punches, saving labor.

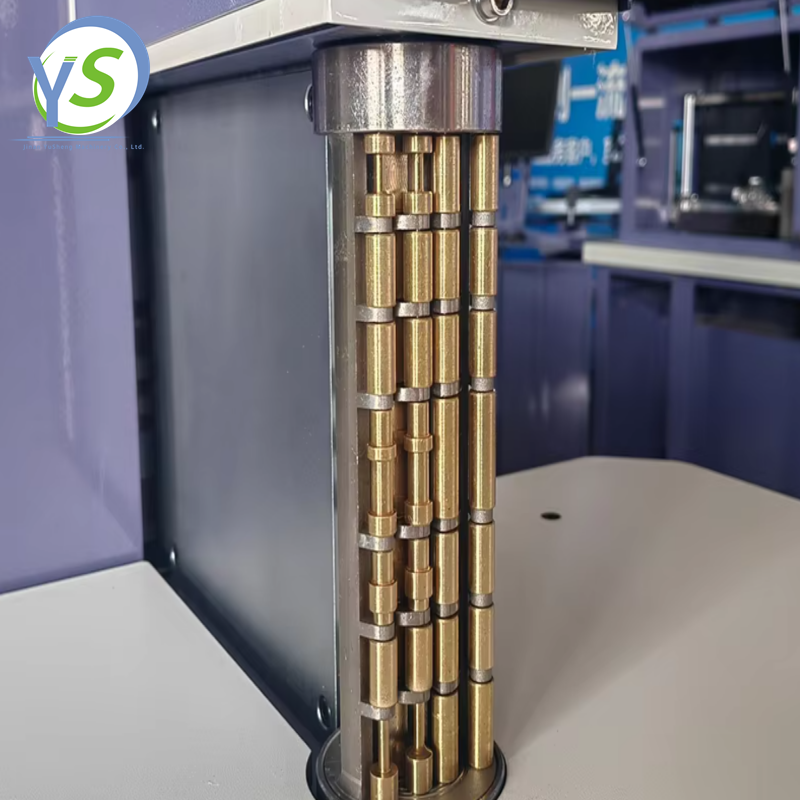

- Screw plus two rails and four sliders for positioning transmission, with greater strength and more stable cutting.

- High power servo control system, high precision, fast speed, high torque, improve working efficiency.

- With length closed-loop control system, the length accuracy is controlled by software, and the error is ≤ 0.1 mm.

- Full chrome plating for machine, Wear-resistant and corrosion-resistant.

- The software system is simple, easy to learn, easy to operate, professional, efficient and thoughtful.

Technical Parameter

| Voltage | 220V 50HZ (Can be customized) |

| Power | 2KW |

| Working pressure | 0.3 ~ 0.8mpa |

| Processing profile width | 15-130mm |

| Application profiles | Stainless steel, galvanized sheet, iron sheet, aluminum, flat metal profiles, act |

| Minimum arc radius | R>3mm |

| Maximum processing thickness | 0.3~1.2mm |

| Length precision | ±0.1mm/M |

| Feeding system | Mechanical hand feeding |

| Bending system | Servo double-knife alternating bending system |

| Punching system | Standard automatic punching system |

| Dimensions | 2600mm*800mm*1550mm |

| Weight | 400 kg |

Machine Details

Product Application

About Jinan Yusheng Machinery

Jinan Yusheng Machinery Co., Ltd. is dedicated to the cutting-edge technology of aluminum profiles, doors, windows, and curtain wall processing equipment, as well as the practical application of processing sites. It has a team of experienced and expert employees in the industry, equipped with a large mechanical processing workshop with complete functions. It is a high-tech enterprise that integrates research and development, production, sales, and service. Since its establishment, the company has been committed to the research and development of energy-saving door and window technology, providing complete assembly equipment for aluminum profiles, ordinary plastic steel profiles, and high-end aluminum insulated glass production lines to the industry. The products cover industries such as industrial aluminum profiles, door and window curtain walls, rail transit, aerospace, industrial manufacturing, and household appliances. The company relies on strong technical expertise, rigorous production and processing, and a complete range of equipment to meet the needs of different investment scales. It can also customize personalized products of different grades according to customer requirements.

Creating value for users is our commitment, taking responsibility for each product is our responsibility, and customer satisfaction is the ultimate goal of our services; Winning customer, employee, and social satisfaction is the driving force behind our progress.

With high-quality products and an efficient service team, Yusheng Machinery looks forward to providing you with high-quality products and services!

Certifications

Our Clients

Packing&Delivery

Service

1). At least 1 year from the date of completion of the commissioning.

2). Free consultation service before, during, and after sales;

3). Free project planning and design services;

4). Free debugging of equipment until everything is functional;

5). Free management of equipments long distance shipping;

6). Free training of equipment maintenance and operating personally;

7). Provide 1 year complete warranty and life-time maintenance service;

Reviews

There are no reviews yet.